The Australian climate is no joke, and without ventilation for your shipping container home, you’re at risk of condensation, mould growth, and a whole lot of discomfort. So, how can ventilation be achieved?

Whether you’ve always purchased a shipping container and want to modify it or are weighing up your options, understanding ventilation and how to implement it is non-negotiable if you want a comfortable space to live or work in. To transform a steel structure into a fully liveable functional space, you need a clear understanding of how airflow works, and more importantly, how to regulate it.

Having a healthy and comfortable home with high thermal performance requires both reliable and thermally efficient ventilation, as well as a high level of airtightness. This article will discuss why airflow is so important, and even more so in a container-based structure, the risks of ignoring ventilation–including airtightness, and the most effective ways to ventilate your space. We also closely look at Sonic Steel’s Heat Recovery Ventilation System.

All homes require ventilation to maintain good indoor air quality. It increases oxygen levels, dilutes and displaces carbon dioxide and airborne pollutants. Ventilation is crucial in energy-efficient homes to maintain indoor air quality and comfort.

Without ventilation, outdoor weather changes can negatively affect the internal atmosphere, and the resulting temperature fluctuations heighten the risk of moisture covering the surfaces inside, which could potentially lead to mould growth and negative health issues.

Since metal is a conductive material, container homes heat up quickly in summer and lose heat in winter. Ventilating them properly helps release hot air in warm climates and supports HVAC systems to maintain a comfortable temperature.

Shipping containers are steel boxes, so without ventilation, internal stale air accumulates faster, which creates an environment inside that is too humid and uncomfortable for you to live in. Ultimately, a lack of airflow can cause many health problems.

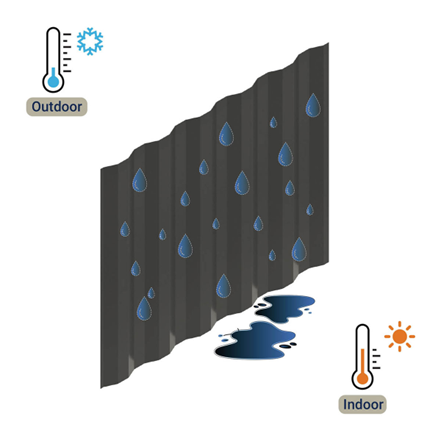

Whenever you cook, shower, or breathe,water vapour is released; metal surfaces easily condense moisture, resulting in water droplets forming on the ceilings and walls.

Long-term condensation issues could result in bacteria and mould growth, which is a major health hazard and likely to exacerbate respiratory problems from chronic exposure.

Some shipping containers are used to carry chemical goods, so when you’re re-purposing them as homes or pop-up businesses, the off-gassing can cause negative health impacts.

Even if these are removed or sealed, some VOC off-gassing can still occur from paints, finishes, insulation, or adhesives. A good ventilation system dilutes and expels these potentially harmful compounds from the interior of your home.

At Sonic Steel, we always use one-trip containers as they are often not used to carry chemicals or harmful products.

Looking to build a container home? Sonic Steel helps with shipping container modifications.

Read: How To Choose the Perfect Size for Your Relocatable Shipping Container Home!

Natural ventilation uses wind and temperature differences to move fresh outdoor air indoors through openings (windows, doors, vents). As such, ventilation rates vary depending on weather and how often occupants open/close windows or doors. Adequate ventilation using only windows and doors requires the occupants to open sufficiently sized windows at all times of the year. While natural ventilation is better than having no ventilation at all, there are inherent limitations as follows:

In short, natural ventilation is useful and low-cost, but unreliable and risky when used on its own.

So, is natural ventilation still important? Yes. Strategically placed windows and vents around your container home help with natural airflow, especially during milder weather. These methods complement mechanical systems (HRV) to keep your living environment pleasant.

Mechanical ventilation uses fans to bring outdoor air in and distribute it indoors. There are two common systems, such as: exhaust air ventilation and mechanical ventilation heat recovery (MVHR). Mechanical ventilation is essential in airtight buildings where natural airflow is limited.

Exhaust Air Ventilation uses extractor fans (commonly in kitchens and bathrooms) to remove humid air. These must vent outdoors, not into roof spaces/cavities, and need draught stoppers to prevent unwanted air exchange when not in use. Replacement air for exhaust fans normally comes through infiltration (in leaky homes) or opening windows (in airtight homes), which may increase discomfort and energy use because of untempered outside air.

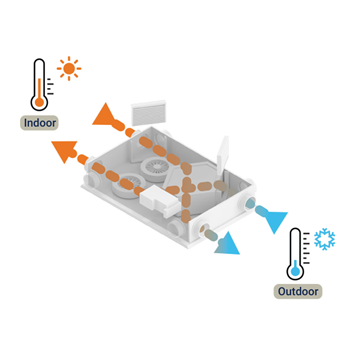

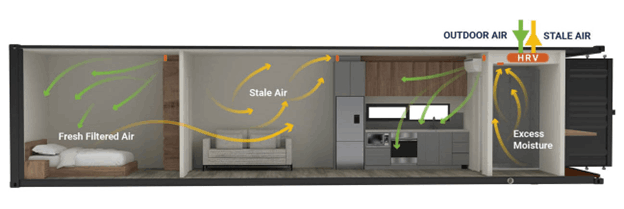

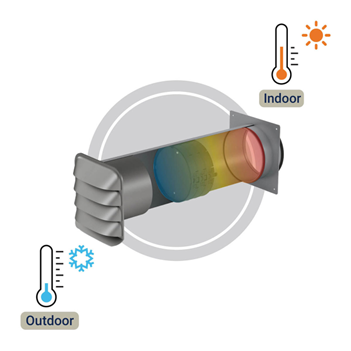

Mechanical Ventilation Heat Recovery (MVHR) uses a Heat Recovery Ventilator (HRV) to provide full-house ventilation for airtight homes. HRVs capture heat from outgoing humid air with a heat exchanger and use it to temper incoming fresh air. Some of the benefits are:

In short, HRV systems are advanced, efficient, and maintain high air quality, but require airtight homes and expert installation.

Airtightness can improve the thermal performance of your home by reducing the ingress of hot air in summer and cold air in winter. Improving air tightness is one of the most cost-effective and easiest ways to improve your thermal comfort and reduce energy costs.

Airtightness is about limiting the unintentional introduction of outdoor air into a building, or limiting the loss of indoor air to the outside. The greater the airtightness, the more controlled levels of temperature and humidity are to ensure comfort.

Windows and doors that have been designed to encourage natural ventilation when open are beneficial. But windows and doors that are poorly sealed, allowing cold draughts in winter or hot draughts in summer, are a problem.

Air typically leaks through:

In shipping container homes, airtightness is crucial for energy efficiency, indoor air quality, and moisture control. Shipping containers are designed to be airtight in order to protect the goods from the elements and oceanic conditions. It is this inherent airtightness that can either be beneficial or disadvantageous, depending on how it is addressed.

Because shipping containers are fully welded, they are airtight by nature. If and only when insulated properly, this would help keep the internal space thermally efficient without leaking warm or cool air to the outside. On the other hand, airtightness also means limited air exchange, which is problematic for ensuring comfort and can lead to negative health issues.

Stagnant air directly contributes to mould growth by trapping moisture and humidity within a space, creating the damp conditions necessary for mould spores to thrive and multiply. Lack of ventilation allows condensation to form on surfaces, providing the moisture that mould needs to grow on organic materials like timber, fabrics, and dust.

So how can a shipping container home be both airtight and well-ventilated at the same time?

Container homes are usually designed with multiple cut-outs for windows and doors, which makes sealing, for both waterproofing and airtightness, more complex than in conventional timber-framed buildings. While others rely solely on sealants, Sonic Steel fully welds all cut-outs to ensure everlasting and completely airtight connections.

A highly airtight container home must include controlled ventilation (mechanical heat recovery). Relying on cracks or natural leaks for airflow isn’t reliable and risks moisture build-up. The best approach is to combine airtight construction with a quality Heat Recovery Ventilation system.

Let’s explore Sonic Steel’s ventilation system and why it’s so unique by balancing air tightness and fresh air exchange.

Do you need a comfortable, healthy living space? HRVs are used for controlled mechanical ventilation as well as operable windows. Retaining up to 85% of thermal energy, this system exchanges stagnant air with fresh, filtered air.

In Australia, especially in colder climate zones, humidity levels go high and low throughout the year, so condensation is more likely, and you need a ventilation system that adapts to these changes. The HRVs also maintain a constant level of humidity inside the home, eliminating any moisture generated by washing, cooking and breathing. Since the home is thermally efficient, you’re relying less and less on air conditioning.

HRVs come in many forms and brands. Sonic Steel only uses quality and reputable brands (like Zehnder or S&P) for optimal performance, durability and peace of mind.

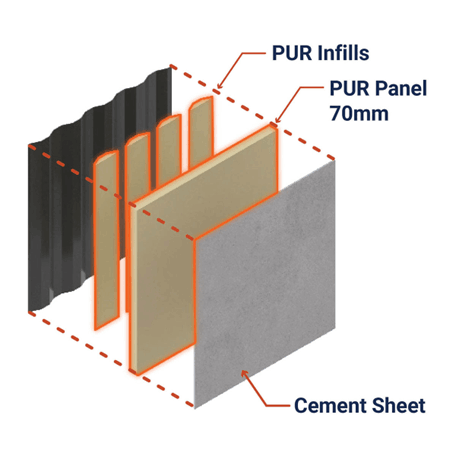

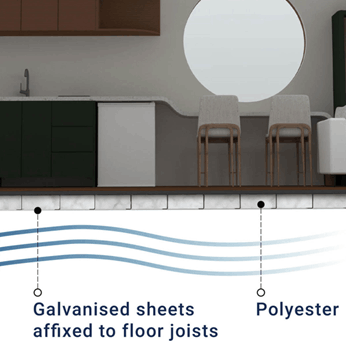

Sonic Steel’s VenSulation system isn’t just about ventilation; it also includes a robust insulation system. A shipping container is more difficult to insulate as it has limited width and fully-welded corrugated walls. In order to avoid condensation, moisture must not come into contact with the internal metal surface.

Sonic Steel uses block-moulded polyurethane (PUR) panels (not spray foam!) as a vapour barrier between the container wall and interior space. These panels are also CNC-cut to match the container's corrugated walls to eliminate air gaps and moisture penetration.

Sonic Steel polyurethane panels are manufactured in Australia by a block-moulding method, then stored for at least 30 days to cure and minimise off-gassing. These blocks form a barrier that eliminates air gaps and maintains a consistent indoor temperature.

We place grooves carefully to accommodate electrical cables and plumbing pipes. This means you’ll have a neat and concealed system.

There’s also underfloor insulation. Overlooked by some, not insulating the floor can account for a massive amount of heating and cooling loss; insulation protects you from termites and the underside from bushfire attacks.

Sonic Steel uses ThermalHeart frame systems with 24mm double glazing that are Australian-made. Some of the highlights are:

A fixed air conditioning system is a good option. Ideally, you want an air conditioner that dehumidifies your space too. Sonic Steel shipping containers include Daikin split systems for optimal quality.

The Daikin AC offers reliable, efficient climate control, circulating internal air continuously to maintain the indoor temperature you desire. Additionally, an inverter technology is helpful as it adjusts the compressor speed based on your cooling demands. Expect a stable indoor temperature, all in all.

The Naber THERMOBOX prevents backdraught through the kitchen exhaust, working without electricity and uses air as an insulator.

What does it consist of? Triple dampeners are arranged, one behind the other, and sealed by a magnet. When these are closed, the flaps form two chambers that trap air (which is a poor heat conductor), cutting back heat loss.

THERMOBOX makes sure that cold or hot air stays out even during powerful winds. It also prevents cooling and heating energy from escaping when the range hood isn’t being used.

Sonic Steel maintains tight seals to minimise energy leaks, yet balances this with effective ventilation. There are two options available to you!

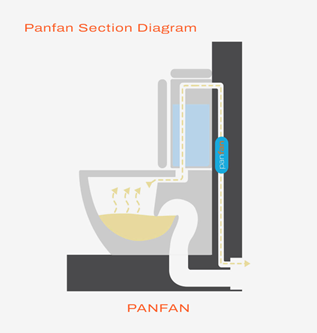

Panfan Odourless Toilet maintains a pleasant, clean atmosphere with a ventilation system that extracts odours from the toilet bowl and vents them outside.

Operating quietly, the Panfan operates quietly and barely uses energy. Your bathroom will always feel fresh!

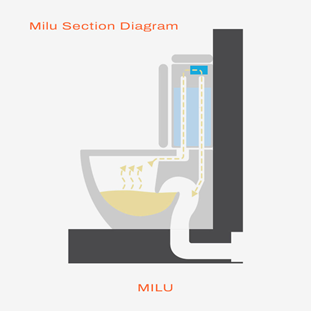

Milu Odourless Toilet has a quiet fan built in that quietly extracts odours and discharges them into the sewer, so you don’t have to worry about bad smells getting into your bathroom. The Milu also uses an easy-to-clean, rimless bowl with a powerful flush, and the soft-closed seat/lid is comfortable and convenient for all users.

Read: Understanding the Durability of Shipping Container Homes: How Long Do They Last?

If you’re looking for a compact lifestyle, the Mark II can be used as an office space or a self-sufficient living space. 20ft, it is not limited by size!

Great for a backyard office or a granny flat, it’s also a cost-effective option to maximise your land use.

View our brochure to learn more.

The Mark V design is spacious enough to work for a young family with small children. A compact, functional kitchen and living space, you don’t need to compromise space or comfort.

Rooms are bright and welcoming with Velux skylights, large awning windows, and clean air is well circulated! What are some quality features?

Have you been wanting to build a shipping container home in VIC, NSW, SA, or anywhere across Australia? Check out our completed projects for inspiration.

We’re passionate about creating quality and making a difference. Working in the shipping container industry since 2014, Sonic Steel expanded from repairs/modifications to constructing unique, functional container homes. We want to bring your vision for a tiny home to life.

Drawing from an architectural background, we bring our technical and engineering knowledge to the table. If you’re seeking a sustainable getaway for your land or a commercial shipping container, we always give you the best of what we have to offer.

Contact us by calling 03 9364 8797, emailing enquiry@sonicsteel.com.au or visiting our showroom in Brooklyn, Victoria, by appointment. All of our containers are fully customisable; all you need to do is ask us for a DIY shipping container job and discuss our building methods and materials.

With Tiny Home Expos in VIC, NSW and WA in the coming months, we are offering DISCOUNTED DELIVERY (*up to $5000) to each state the Expo is in exchange for using your project as a display at the show. Offer expires 12 weeks before each expo and is limited to one project per expo. Reach out to us now to secure your spot!

How to Maximise Space in a Shipping Container Home: Secrets Revealed

Can You Modify a Shipping Container? Exploring Your Options

From Steel Box to Dream Home: How Smart Ventilation Transforms Container Living

Top 5 Benefits of Opening a Shipping Container Cafe: Why It’s a Smart Choice

How to Choose the Perfect Size for Your Relocatable Shipping Container Home