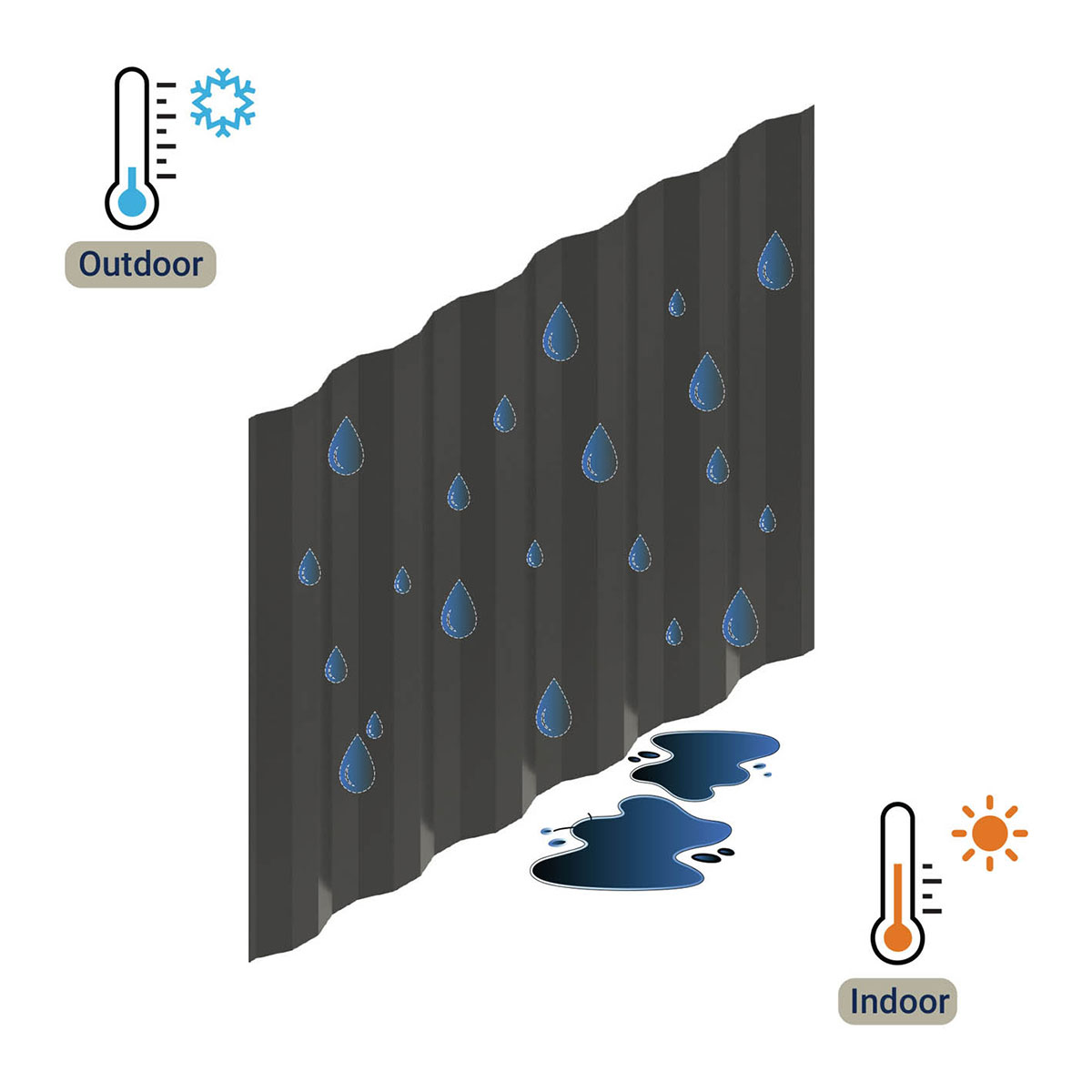

Proper insulation is incredibly important for every dwelling. Insulating a container is even trickier than a normal home, due to the limited width and the fully welded corrugated metal walls, not to mention the condensation issue, which occurs when warm, moist air comes into contact with the cold metal surface. Our insulation method was developed to eliminate the risk of condensation.

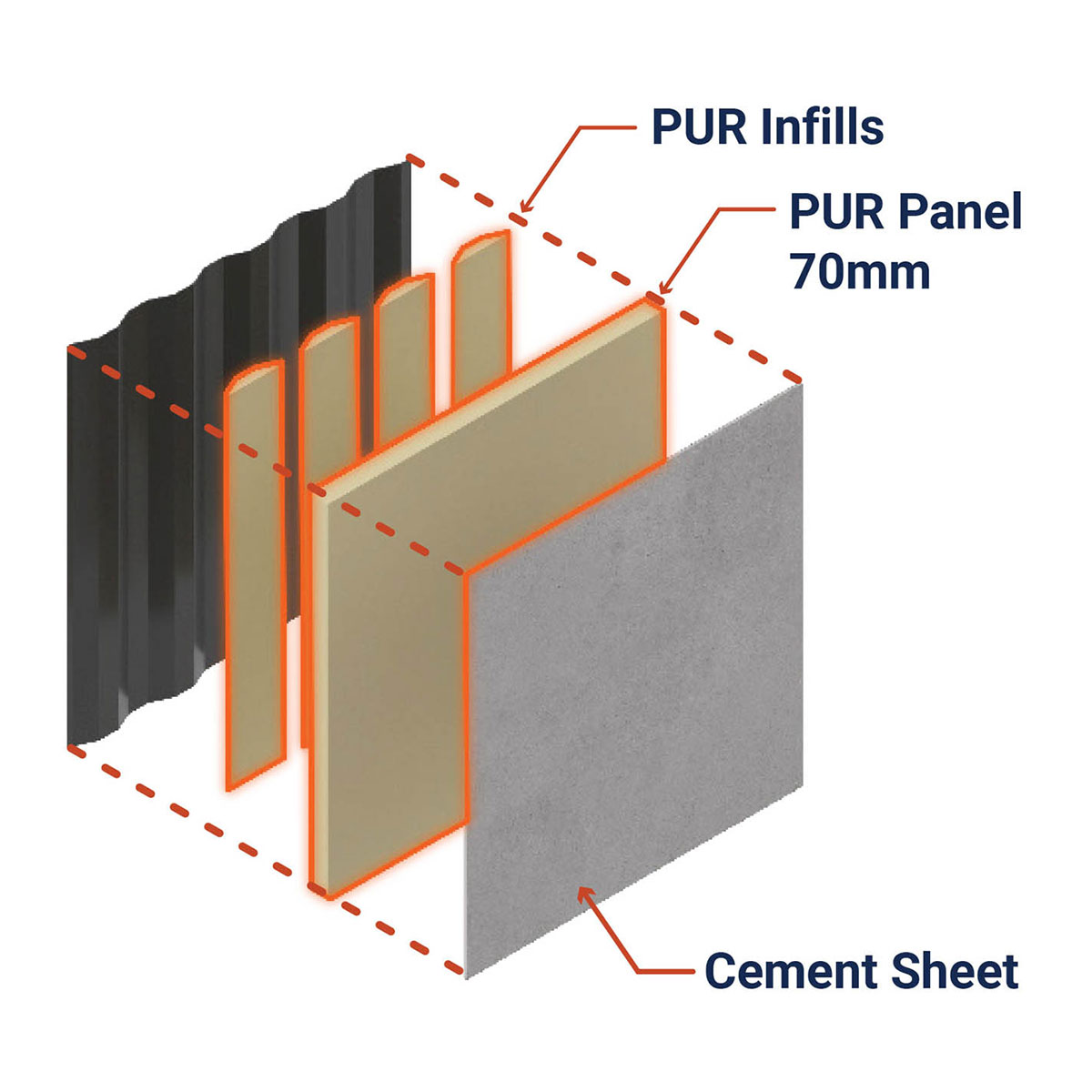

To prevent condensation (a precursor to mould growth), moisture must NOT come into contact with the internal metal surface. We use polyurethane (PUR) panels (not spray foam) as a vapour barrier between the container wall and the interior space, maximising thermal and sound insulation whilst eliminating the internal metal surface’s exposure to moisture. We choose PUR for its vapour resistance and the superior insulating performance compared to EPS and other materials. As a result, this can both reduce your energy bills and lower your carbon footprint.

Our polyurethane panels are manufactured in Australia by block-moulding method, then stored for at least 30 days to cure and minimise off-gassing. These blocks are then precisely CNC-cut to fit into the corrugations of the container panels, forming a robust barrier that eliminates air gaps and help maintain a consistent indoor temperature and prevents condensation, keeping your container home warm during chilly winters and cool during hot summers.

Within the polyurethane panels, we strategically place grooves to accommodate electrical cables and plumbing pipes, ensuring a neat and concealed system, maintaining the aesthetics of the interior.

Our unique insulation technology blends in seamlessly with the structural design of each container home. This ensures that you receive all of the functional benefits without losing the signature visual appeal of shipping container homes.

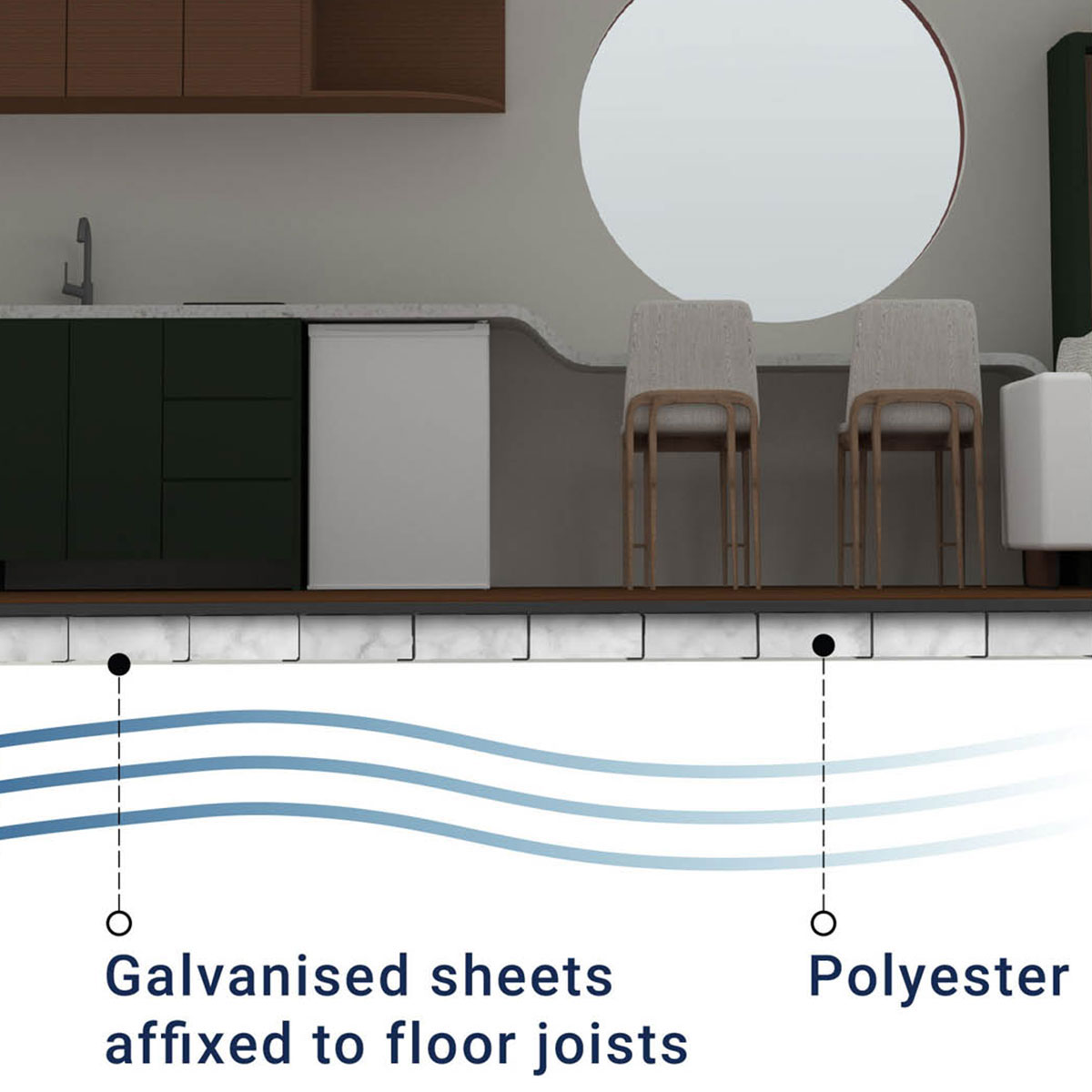

Whilst overlooked by most people, not insulating a shipping container floor can account for up to 20% loss of heating and cooling energy in your container home. Underfloor insulation is part of our inclusion to maximise your home’s thermal efficiency. The added benefits also include: termite and pest deterrents, protecting the underside against bushfire attacks (which is one of the requirements on high BAL ratings).

We insulate between the container’s crossmembers/ floor joists with polyester for its moisture-resistance as well as being a recycled material. The whole underside is then closed off by galvanised metal sheets to keep the polyester in place, as well as providing extra protection. This also contributes to the airtightness of the floor structure.

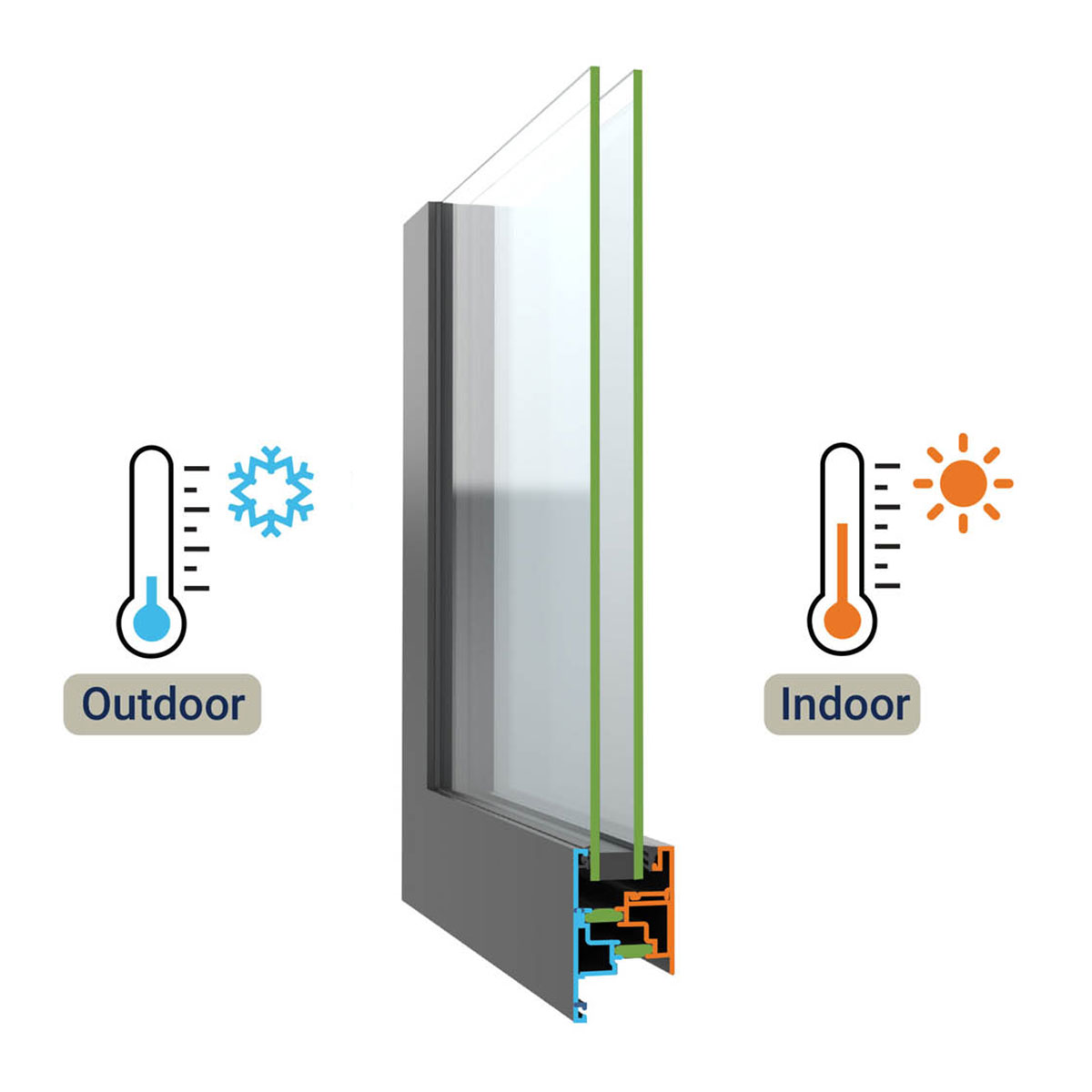

All of our high-performance windows and doors are Australian-made and super efficient, using double-glazed units with Low-E coating as well as thermally-broken frame by ThermalHEART.

ThermalHeart windows work by incorporating a thermal insulator within the aluminium frame. This insulator, typically a polyamide strip, significantly reduces heat transfer through the window frame. Thermally-broken frame also helps prevent condensation. Double glazing enhances thermal efficiency by using two panes of glass separated by an insulating gas layer. This gas layer reduces heat transfer between the inside and outside of your home, providing better thermal insulation, reducing noise, and lowering energy costs.

Low-E (low-emissivity) coatings further improve the performance of these windows. These coatings are applied to the glass surface and reflect infrared light, keeping heat inside during winter and outside during summer. This results in even greater energy efficiency and comfort, as well as protection from UV rays that can cause fading of interior furnishings.

Together, our high-performance glazing components help maintain a constant temperature for the interior, enhancing overall energy efficiency and comfort.

Insulating your shipping container is crucial if you live in a state with a variable climate. Proper insulation helps maintain consistent indoor temperatures, reducing the need for excessive heating and cooling. It also prevents condensation and moisture build-up, which can lead to mould, rust, and compromised structural integrity.

Sonic Steel’s VenSulation system combines advanced CNC-cut PUR foam insulation with Heat Recovery Ventilator (HRV) units. This dual approach ensures excellent thermal performance and continuous, filtered airflow, addressing both thermal efficiency and condensation issues in diverse climates.

Yes, definitely! Condensation can lead to the following issues:

Our shipping container insulation uses PUR foam blocks cut to fit the container’s corrugations, forming a tight barrier that prevents external air and moisture from penetrating. Coupled with the HRV units, this setup keeps the air circulating within the container, minimising moisture build-up and condensation issues.

While DIY installation is possible, professional installation is highly recommended to ensure accuracy and safety. The intricate process of fitting insulation and ventilation systems is best handled by experts, like Sonic Steel’s skilled team in Melbourne, guaranteeing optimal performance and longevity of your container home’s insulation.

Sonic Steel offers nearly a decade of industry experience, a commitment to innovation with our exclusive VenSulation system, and custom solutions that fit your specific needs. Our methods enhance energy efficiency, reduce condensation risks and maintain the aesthetic and structural integrity of your container home, making us the preferred choice for shipping container insulation in Australia.