It’s probably fair enough to say that we like them just because of the way they are. In case you need more ticks on the pros side, here are a few:

If you love shipping container homes, you’re probably aware of their inherent challenges that relate to:

These are not individual challenges but rather parts of a system that correlate to form an efficient and healthy living space. That said, condensation in container homes is still public enemy No. 1, which causes discomfort and leads to mould growth within the home if not resolved properly.

Containers are built to be air and watertight, which means there are no natural means of air exchange, compared to leaks and cracks that exist in a traditional home, so any moisture within the container would potentially form condensation (also called sweating) when certain conditions are met. We all know this phenomenon with a cold can of drink on a warm day. The same thing would be happening on the container’s metal walls. Because container walls are fully welded, condensation droplets are trapped in the wall cavity, which would rot out any organic material (timber studs, plaster boards, etc.) and promote mould growth inside the home.

Our unique VenSulation system comprises of two parts: For ventilation, we regulate the humidity level so there is no build-up of excess moisture, through the mean of Heat Recovery Ventilation (also called HRV); for insulation, we eliminate air gaps within the wall cavity so no moisture could come into contact with the metal surface and form condensation.

A. Because containers are more airtight than conventional homes, they need to (as many would think) rely on natural ventilation through windows and doors for air exchange, but this would mean discomfort and decrease the thermal efficiency, especially on a hot/ cold day. That is why we added mechanical ventilation to our system. We use high-quality Heat Recovery Ventilation (or HRV) systems – like Zehnder or S&P, which can retain up to 85% of thermal energy while bringing in fresh filtered air in exchange with stagnant air. So, on a cold winter night, you can keep warm with all the windows shut, and still be able to enjoy the ventilated fresh air, all from just 8W of power. The HRV also maintains a constant humidity level inside the home by eliminating excess moisture that’s generated by cooking, washing and breathing. Having a HRV helps make your home more energy efficient as it reduces the load on your air conditioning system, and most importantly, it ensures a healthy and comfortable living space.

B. Insulating a container is trickier than a normal home, due to the limited width and the corrugated metal walls. To prevent condensation (a precursor to mould growth), moisture must NOT come into contact with the internal metal surface. To achieve this, we CNC-cut cured PUR blocks (not spray foam) into the same profiles as the metal wall in order to fill in the corrugations, followed by flat PUR panels, usually 70mm. As a result, the PUR acts as a vapour barrier between the container wall and the interior space, maximising thermal and sound insulation as well as eliminating air cavities. We choose PUR for its vapour resistance and superior insulating performance compared to EPS and other materials. We also install insulation underneath the floor to stop the loss of warm/ cool air due to draught.

To ensure energy efficiency, integrate high-efficiency ventilation systems like HRVs that consume minimal energy while providing optimal air exchange. Pairing these systems with proper insulation, such as Sonic Steel’s VenSulation system, will reduce energy costs and improve indoor climate control, making your container home more sustainable.

Yes, natural ventilation methods can be used effectively, but not on its own. Incorporating strategically placed windows and vents around your container home can enhance natural airflow, especially during mild weather periods. These methods can complement mechanical systems to maintain a pleasant living environment.

There are three common methods for insulating container homes: batt insulation, Coolroom panel (EPS) and spray foam. Although batt insulation is effective in traditional homes, they are vapour permeable and with the airtight metal walls, the trapped moisture can promote mould growth due to the lack of air circulation. Installing vapour barrier membranes could slow down this process, but excess moisture would eventually come into contact with the metal walls and form condensation in certain conditions. EPS/ Coolroom panel insulation faces the same issue as there is still air cavity within the walls.

Spray foam (closed cell) is one of the best vapour barriers to avoid condensation when applied properly. However, because the foam is created by a chemical reaction, the application must ensure that the ingredients react completely, and no residue is left that could cause off-gassing. This is not a consistent process as it depends on atmospheric factors such as temperature, humidity and pressure, and should only be carried out by professionals.On the other hand, our PUR panels are block-moulded by industry specialists in a controlled environment to ensure quality and consistency. Once cured, the foams are stored for at least 30 days before cutting and installing so there’s no concern with off-gassing.

Our polyurethane (PUR) has an R-value of 0.335m2K/W per 10mm, so higher R-value can be achieved by thicker profiles. We can achieve R2.9 with our 70mm walls (70mm at the thinnest section and 102mm at the thickest section – due to the corrugated profiles) and can design to comply with the 7-star rating equipment. For the ceiling, it would be R3.4 with 90mm PUR + 20mm infills, this can be increased with an external roof. It’s also worth noting that PUR can perform better than batts insulation of the same R-value when considering other factors such as moisture control and air movement, all of which are well addressed in our system. We work with an energy assessor and can provide you an energy rating certificate.

Insulating your shipping container is crucial if you live in a state with a variable climate. Proper insulation helps maintain consistent indoor temperatures, reducing the need for excessive heating and cooling. It also prevents condensation and moisture build-up, which can lead to mould, rust, and compromised structural integrity.

While DIY installation is possible, professional installation is highly recommended to ensure accuracy and safety. The intricate process of fitting insulation and ventilation systems is best handled by experts, like Sonic Steel’s in-house trades, guaranteeing optimal performance and longevity of your container home’s insulation.

We only use single-trip containers (also called new builds), which only transport goods for the one trip from the manufacturer to us. This means that the cargos are only limited to dry and non-perishables, usually furniture, white goods, etc. so that the condition of the container remains brand new.

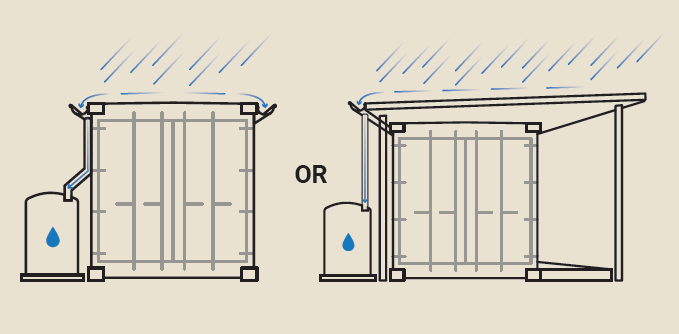

The roof of the container is designed to not hold water as it is slightly curved. All joints on the container are also fully welded so that they are watertight. People normally face problems with rusted roofs due to the use of second-hand containers that are damaged and have low points on the roof where water collects and rusts out the steel over time. We use new containers and thus eliminate the issue. Another preventative method includes applying an extra waterproofing membrane, which would be at extra cost and might not be necessary for the purpose of preventing water leakage but does provide peace of mind with extra thermal protection. Waterproofing is one of our utmost priorities besides ventilation and insulation. All our cut-outs and framings are fully welded, and all external electrical points (if any) are covered with fully welded plates to avoid direct exposure to the rain. Our bathrooms are also waterproofed in compliance with the building code.

We suggest that you have a roof over built on top of the container once on-site for rainwater collection and extra thermal protection. We can also organise this to be built at our factory, but it must not exceed the height limit for road transport (if going through tunnels or overhead cables). Alternatively, two long gutters can be fitted along the sides of the container’s roof, as the water will drain off in this direction.

We work with Great Escape Finance who specialises in Tiny Homes lending. You can find more at: www.gefinance.com.au/sonic

All of our windows and sliding doors come with flyscreens.

Yes, we use Taubmans Professional Undercoat and Taubmans Endure – both are top range and low VOC from Taubmans – to ensure a superior and easy-to-wash finish. The Endure Interior range also protects homes against the growth of mould, mildew and bacteria with advanced anti-microbial technology.

We use Marine Grade paint, which is specifically formulated for containers to withstand all weather conditions. Please note that regular maintenance and care play an important role in the coating’s durability. Our supplier’s guarantee is 15 years in oceanic conditions, so it should last much longer than that being away from such harsh conditions.

We custom-build all of our projects to suit individual budgets and requirements. We believe in quality and uniqueness when it comes to living styles. From room sizes down to the locations of power points, we make sure that it’s designed and built to suit your lifestyle.

Yes, of course. It’s important to mention that with projects where multiple containers are joined together, the cost would be somewhat similar to a conventional build, sometimes even more (due to transport, assembly, engineering and extra fabrications, etc.) depending on the design and the location. However, the advantage is that they’re prefabricated so the building time is much less. Also, if your property is in a remote area, it might be that building container homes is more affordable as finding tradies that go there might be difficult and costly, although this is not always true. If you’re fascinated about containers as much as we do, then the aesthetic appeal is definitely part of the formula.

Absolutely. We work with transport companies that service Australia-wide. There are two ways to load/unload a container home: with a side loader truck (more affordable) or with a crane (more costly). If you are within Victoria and have reasonable access to a semi-trailer, the home can be delivered by a side loader. If you are interstate, it would be more affordable to use a side loader only for loading and unloading (from a local haulage company), and to travel the long distance by a skel trailer instead. If you have limited access to the allocated spot for the home, it would be best to engage a crane to put it in place.

Yes, subject to access, overhead services and a traffic management plan.

This would depend on the soil types. Generally, containers are designed to only need support in the corners. Extra supports will be required depending on the amount and sizes of doors and windows, and to be specified by an engineer. From experience, our container homes are normally located on 6 or 8 concrete footings/ pads. Other footing types are also available subject to the engineering design.

We can do both custom builds (any length between 20ft and 50ft) and standard builds (20ft and 40ft). 20ft is 2.4m x 6m and 40ft is 2.4m x 12m (approximate external dimensions). We only use Hi-Cube containers, which are 2.9m high (external). We can also join multiple containers to form double-storey or wider rooms.

The short answer is that many of our previous projects were compliant with the NCC and approved to be built across the country (VIC, QLD, NSW and SA) as Class 1A dwellings. Unfortunately there’s no straight answer when it comes to planning regulations, as it varies between each council and state. The general rule is that any habitable structures intended for permanent occupation would require a building permit or compliance certificate, be it a caravan, container home, or home on wheels. This would differ from council to council, so you would need to find out on the case-by-case basis. Your best research would be to contact your local council and check with them. If you need help, just let us know and we can assist you.

They can be classified as either portable/ transportable dwellings, or as permanent structures (e.g., class 1A), depending on your council’s specifications and their planning scheme.

The best research would be to do your own due diligence on the council’s website or check with them directly. If you need our assistance, please let us know and we should be able to help you with the right information.

We work with Council Approval Group and architects/planners who specialise in town plannings/ DAs across the country.

Yes. we have had projects approved across Australia. Some of the councils are: Bellingen Shire (NSW), Home Bland Shire (NSW), Wollongong City (NSW), Southern Mallee District (SA), Tumby Bay District (SA).

Our builds are adaptable to any toilet type of your choice, e.g., flush, composting, cassette (caravan style), incinerating, etc.

Absolutely. There are a range of options on toilet types, solar systems and battery sizes, etc. Please reach out to our friendly team for a detailed discussion.

Off-grid living offers a unique opportunity to achieve financial independence, reduce your environmental impact, enhance your self-sufficiency, and improve your overall well-being. While it requires careful planning, dedication, and resourcefulness, the rewards of living a more sustainable and fulfilling life can be truly transformative.

Off-grid living, while rewarding, comes with its own set of challenges:

Overall, while off-grid living can be incredibly rewarding, it’s important to be realistic about the challenges involved. Thorough research, careful planning, and a willingness to adapt and learn are crucial for a successful off-grid experience

Our homes come with pre-installed electrical work and plumbing, which is ready to be connected to the main services once on-site.

We can design and build to the required BAL and comply with the local council’s regulations. Our builds can achieve BAL29 by default, or higher with additional measures.

Shipping containers are inherently strong and are designed for cyclonic/ oceanic conditions. However, proper anchoring to the foundation and additional structural reinforcement will need to be engineered to comply with the building requirements.

The main bedroom is 2.19m wide, the Double mattress is 1.38m x 1.88m, Queen is 1.53m x 2.03 and King is 1.83m x 2.93m. Please note that these are mattress sizes only, bed sizes can vary or can be custom-built to be the same size as the mattress.

Our standard 40ft models take between 8-10 weeks to build, excluding the design process. Our queue time would vary depending on the number of orders at the time.

All our container homes are covered with a 10-year structural and 2-year non-structural warranty. (terms and conditions apply)